Ever wondered how to make custom melamine plates that perfectly capture your brand’s essence, celebrate a special occasion, or simply stand out? You’re in the right place! Getting custom printed melamine plates is more than just uploading a photo; it’s a fascinating journey from idea to tangible product. This guide will walk you through the entire process, ensuring your vision for personalised melamine plates becomes a stunning reality in 2025.

Last Updated: June 6, 2025 | Estimated Reading Time: 12 Minutes

Why Would You Want Custom Melamine Plates Instead of Off-the-Shelf Options?

While readily available plates serve a purpose, creat your own plates offer a unique way to express individuality, reinforce branding, or create memorable gifts and merchandise.

What are the key benefits of choosing “custom melamine plates” for your brand or personal use?

Opting for custom design melamine plates gives you unparalleled control. You can:

- Boost Brand Recognition: Feature your logo, brand colors, and unique designs, turning every meal into a branding opportunity for restaurants or corporate events.

- Create Unique Merchandise: Develop one-of-a-kind plates for sale, themed around art, characters (like a “Disney melamine plate” concept if you have the license), or special interests.

- Personalize Events & Gifts: Design plates for weddings, anniversaries, or as thoughtful, durable gifts. Think melamine Christmas / Halloween / Easter / Thanksgiving plates that become treasured keepsakes.

- Match Decor Perfectly: Ensure your tableware perfectly complements your restaurant’s theme or home interior design.

- Control Quality & Material: Choose the specific grade of melamine (like A5 food-grade) or opt for bamboo fiber plates for an eco-friendlier touch.

Who typically benefits most from ordering custom plates?

A wide range of clients seek out customization:

- Restaurants, Cafes, and Hotels: For branded tableware that enhances the dining experience.

- Businesses & Corporations: For promotional items, corporate cafeterias, or client gifts.

- Designers & Artists: To bring their artwork to a functional, everyday product.

- Event Planners: For themed events requiring unique tableware.

- Retailers: Looking for exclusive product lines.

- Individuals: For special occasions, personalized gifts, or unique home use.

Where Can You Get Personalised Melamine Plates Made (and Where Can’t You)?

Understanding where to source your plates is crucial for true customization.

Why are online marketplaces like Amazon/eBay and local supermarkets usually not options for true customization?

Platforms like Amazon or eBay, and your local supermarket, are primarily retailers. They sell pre-manufactured, off-the-shelf products. While some might offer basic personalization (like adding a name to a pre-made design), they don’t typically provide the deep customization needed for unique shapes, specific Pantone color matching, or intricate all-over prints.

Why is finding a specialized melamine plates manufacturer often necessary?

For genuine customization – where you control the design, material, shape (potentially), and finish – you must engage directly with an experienced melamine plates supplier who has strong relationships with factories. These experts understand the production process, material capabilities, and artwork requirements.

Industry Insider Tip: Don’t limit your vision to just a surface print. A capable manufacturer like Duramela can offer customization in shape (using existing molds or creating new ones), material choice (A5, A1, bamboo fiber), base material color (custom PMS), and even specialized finishes beyond standard gloss. Discuss the full spectrum!

Understanding the Scope of Customization: Beyond Just a Print

True customization goes far beyond just printing a logo. Consider these aspects:

| Customization Aspect | Description | Implication for You |

|---|---|---|

| 🎨 Print/Design | Your unique artwork, logo, pattern, or theme. | Full creative freedom. Ensure high-resolution vector artwork for clarity. |

| 📏 Shape & Size | Utilize existing factory molds (cost-effective) or invest in a new custom mold. | New molds offer ultimate uniqueness but add cost and time. Check supplier catalogs first. |

| 🌱 Material | Choose A5 food-grade melamine, budget A1, or eco-friendlier bamboo fiber. | Impacts durability, safety, cost, and aesthetic. (More on this below!) |

| 🌈 Base Color | The melamine itself can be produced in a custom PMS base color before printing. | Creates a richer, integrated look rather than just a white plate with a print. |

| ✨ Finish | Standard gloss is common. Some suppliers offer matte or textured finishes. | May affect print vibrancy or ease of cleaning. Discuss with your supplier. |

What’s the Typical Process to “Design Your Own Plate” with a Manufacturer?

Ready to create your own plate? Here’s a general roadmap:

How do you start the conversation with a supplier?

Reach out with a clear idea of what you want. Initial contact should include:

- Your concept or design idea.

- The intended use (e.g., melamine restaurant plate, promotional item).

- Roughly how many plates you might need (quantity).

What information about plate style, size, and quantity will they need?

Be prepared to provide details on:

- Plate Style: Round, square, oval, coupe, rimmed, sectioned?

- Size: Diameter for round plates, dimensions for square/rectangular. Specify if it’s a melamine dinner plate, side plate, bowl, etc.

- Quantity: This impacts pricing and whether custom molds are feasible. (See MOQs below).

- Design Details: Number of colors, print area (full bleed, center logo, rim design).

Can manufacturers help if you need a unique shape or size not in their standard catalog?

Yes, many can. This involves creating a new steel mold.

- Mold Considerations: Factories often have hundreds, even thousands, of existing molds. Using an existing mold is the most cost-effective and quickest option.

- New Mold Investment: If your vision requires a truly unique shape or size not in their catalog, a new mold is necessary. This is a significant investment (typically 800-1000 USD, depending on complexity and size) and adds several weeks to the initial production timeline. This is usually viable for large orders or high-value product lines.

Choosing the Right Material: A1, A5, or Bamboo Fiber Melamine?

The material you choose impacts durability, safety, cost, and aesthetics. This is a critical decision for your plates.

| Material Type | Composition & Key Features | Best Suited For | Safety & Compliance |

|---|---|---|---|

| 🥇 A5 Food-Grade Melamine | 100% melamine resin. High durability, dishwasher safe, excellent print quality, glossy. | Most tableware: quality retail, corporate gifts. The industry standard. | FDA, LFGB, BPA-Free compliant. |

| 🥈 A1 Melamine | Higher % of urea-formaldehyde with melamine. Cheaper, less durable, lower heat resistance. | Very budget-conscious projects, trays, or items not for direct, prolonged contact with hot/acidic food. | Food-grade compliance MUST be verified. Not always suitable for all food uses. |

| 🌿 Bamboo Fiber Melamine | Bamboo powder mixed with a binder (often melamine resin). Eco-friendlier aesthetic. | Eco-conscious brands, natural-themed settings. Good durability and print quality. “Custom bamboo melamine plates.” | Often shares compliance with A5 if high-quality binder is used. |

Industry Pain Point: Some clients are tempted by A1 melamine’s lower cost without fully understanding its limitations in durability and food safety, potentially leading to dissatisfaction. Always prioritize safety and the intended use of your plates. For food contact, especially in restaurants, A5 is strongly recommended.

Artwork and Design: How Do You Prepare Your Vision for “Personalised Melamine Plates”?

Your design is the star. Proper artwork preparation is key for a professional finish.

What file formats (e.g., vector AI files) are required for clear printing on your design?

This is crucial: Suppliers need vector artwork.

- Preferred Formats: Adobe Illustrator (.ai), .eps, or .pdf files where all text has been converted to outlines/curves.

- Why Vector? Vector files can be scaled to any size (from a small logo to a full plate print) without losing clarity or becoming pixelated. A JPEG or PNG, while fine for web use, is often inadequate for sharp, professional printing on physical products.

- “Garbage In, Garbage Out”: The factory uses your artwork to create “decal paper” with eco-friendly, food-safe inks. The quality of this decal is paramount. Poor artwork results in fuzzy lines, incorrect colors, and an unprofessional look.

What types of designs are popular (e.g., logos, holiday themes, landscapes, cartoons)?

The sky’s the limit! Popular choices include:

- Logos & Branding: For businesses and restaurants.

- Holiday Themes: Melamine Christmas plates, Halloween plates, Easter plates, Thanksgiving plates.

- Artistic Designs: Landscapes, abstract patterns, illustrations, cartoons.

- Photographs: High-resolution photos can be used, but discuss feasibility with your supplier.

- Personalized Text & Monograms: For gifts and special events.

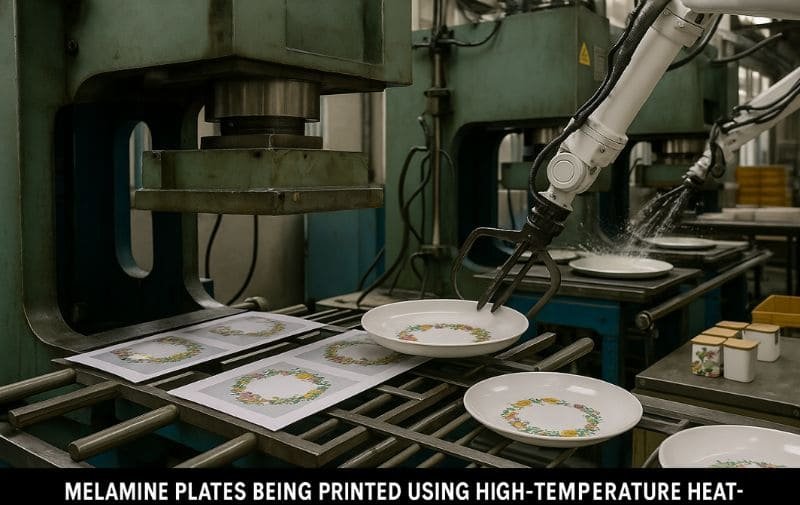

How is the printing (decal paper with eco-friendly ink) actually done?

The most common method for melamine plate printing involves:

- Decal Creation: Your vector artwork is used to print designs onto special decal paper using food-safe, eco-friendly inks.

- Application: This printed decal is precisely hand-applied to the pre-formed melamine base or placed directly into the mold.

- Molding: The melamine material and the decal are then placed in a heated steel mold under high pressure. This process fuses the decal into the melamine, making the design permanent and durable – it’s not just a surface print that can easily scratch off.

- Curing & Polishing: The plate is cured for hardness and stability, then edges are smoothed and the plate is polished.

Unique Perspective: The skill of the factory operators in placing these decals and managing the molding process is critical. Precision prevents wrinkles, misalignments, and other defects, ensuring a high-quality finish for your custom design melamine plates.

Understanding MOQs and Cost

Ordering custom melamine plates wholesale involves understanding minimum order quantities and associated costs.

What are typical minimum order quantities (MOQs)?

MOQs vary by manufacturer but typically range from 2,000 to 3,000 pieces per shape/size for custom designs. This is because setting up the machinery and decal printing plates for a custom run has fixed costs that are better absorbed over a larger volume.

How do suppliers handle requests for multiple designs within a single MOQ? Are there extra fees?

This is a great way to get variety!

- Flexibility: Some flexible suppliers (like Duramela, for example) may allow you to split the total MOQ across a few different print designs (e.g., a 3,000-plate order could be 4 designs of 750 plates each).

- Additional Fees: However, expect to pay an additional decal setup fee (or “film output fee” / “printing plate fee”) for each unique design. This fee (often around $150 per design, but can vary) covers the cost of creating a separate set of decal printing plates for each artwork. This is still usually more cost-effective than meeting the full MOQ for each design individually.

Samples and Prototypes: Can You See Your Custom Plate Before Full Production?

Absolutely, and you should. This is the crucial sampling stage.

Is it possible to get a pre-production sample, and what are the associated costs (sampling fee, setup fee)?

Yes, always request a Pre-Production Sample (PPS).

- Costs: Expect to pay a sampling fee (e.g., $50 USD) plus the machine setup fee/decal printing plate fee (as mentioned above, around $150 USD per design). This covers the cost of creating the initial decals and producing a physical sample of your plate with your exact design and chosen material.

Why is getting a sample important for your order?

Never skip the PPS for a new custom design! It’s your only chance to:

- Verify print color accuracy against your specifications.

- Check print clarity, sharpness, and placement.

- Assess the overall quality, feel, and weight of the plate.

- Ensure the material is as expected.

- Catch any errors before committing to a large custom melamine plates bulk order. This small investment can save you from a costly mistake.

Production and Lead Times: How Long Until You Receive Your Plates?

Patience is key when ordering custom products.

What are the typical manufacturing lead times once a design is confirmed?

Once you’ve approved the PPS and placed your bulk order, typical manufacturing lead times can range from 25 to 40 days. This can vary based on:

- Order quantity.

- Complexity of the design and plate shape.

- Whether a new mold is being created (adds several weeks before this stage).

- The factory’s current production schedule.

How do you confirm the delivery schedule with your melamine plates supplier?

Always get a confirmed production and estimated shipping timeline from your supplier in writing when you place your order. Factor this into your own deadlines, especially for events or seasonal products like melamine Christmas plates.

Industry Pain Point & Tip: Custom orders, especially those involving new molds or intricate designs, take time. From initial design finalization to final delivery can easily be 60-120 days or more. Don’t expect Amazon Prime speeds! Plan well in advance.

Navigating Logistics: When Will I Accept My Goods?

Getting your order from the factory to your doorstep involves understanding shipping terms and options.

What are common shipping incoterms like FOB and CIF, and what do they mean for you?

These international commercial terms define responsibilities between buyer and seller:

| Incoterm | What it Means for YOU (The Buyer) | Supplier’s Responsibility |

|---|---|---|

| 🚢 FOB (Free On Board) | You take responsibility for shipping costs & risks once goods are loaded onto the vessel at the origin port. You hire your own freight forwarder. | Delivers goods to the named port of shipment, cleared for export. |

| ✈️ CIF (Cost, Insurance, Freight) | Supplier pays for shipping & insurance to your destination port. You handle customs clearance & inland transport from the port. | Arranges and pays for transport and insurance to the destination port. |

What is DDP (Delivered Duty Paid), and how can it simplify shipping for inexperienced importers (air, sea, rail, truck freight)?

🌍 DDP (Delivered Duty Paid) is often the most hassle-free option, especially for first-time or inexperienced importers.

- Supplier Handles Everything: With DDP, your melamine plates supplier takes care of all shipping arrangements, insurance, customs clearance in your country, import duties, and final delivery to your specified address.

- Transport Modes for DDP:

- Sea Freight: Most common and cost-effective for bulk, but slowest (weeks to months).

- Rail Freight: Good balance of cost/speed for certain routes (e.g., China to Europe).

- Road Freight / Trucking: For final leg delivery or shorter cross-border shipments.

- Air Freight: Fastest but significantly more expensive; best for urgent samples or very high-value, small-volume orders.

Cost Consideration: DDP is convenient, but the costs are bundled. If you’re experienced, you might save money managing your own freight with FOB. Always discuss these options clearly and understand the trade-off between cost, convenience, and transit time.

Ensuring Quality: How Can You Verify Your Wholesale Order?

Protecting your investment means ensuring the final products meet your standards.

What are your options if you’re a first-time buyer concerned about quality?

Reputable manufacturers have in-house Quality Control (QC) processes. However, for added peace of mind:

- Start with a Reliable Supplier: Choose a melamine plates manufacturer with good reviews, transparent communication, and a willingness to provide samples.

- Detailed Specifications: Provide clear, unambiguous artwork and product specifications.

- Approve the PPS: This is your first line of defense.

How can third-party inspection services (like SGS, V-Trust, QIMA) provide peace of mind?

For your first major order, or for very large or critical orders, consider using a third-party inspection service.

- What They Do: These independent companies will visit the factory (usually when a percentage of your order is complete or before shipping) to check against your specifications.

- Checks Include: Print defects (color accuracy, clarity, alignment), physical defects (chips, cracks, warping), correct dimensions, packaging, and sometimes material compliance (if lab testing is requested).

- Cost vs. Benefit: The cost of an inspection (typically a few hundred USD) is often a small price to pay to avoid receiving a large batch of faulty custom melamine plates.

So, Are You Ready to “Create Your Own Plate” and Make an Impact?

Embarking on the journey to make your own melamine plates is exciting!

What are the key takeaways when planning to order?

- Partner Wisely: Choose a knowledgeable and transparent supplier or manufacturer.

- Artwork is King: Provide high-quality vector artwork.

- Material Matters: Select the right melamine grade (A5 for most food uses) or bamboo fiber for your needs.

- Sample, Sample, Sample: Always get and approve a Pre-Production Sample.

- Plan Ahead: Custom production and shipping take time.

- Budget for Extras: Factor in sampling, setup fees, potential mold costs, and shipping.

Who is the ideal partner for bringing your custom plates vision to life?

The ideal partner is a custom melamine plates company that:

- Communicates clearly and promptly.

- Has experience with diverse customization projects.

- Offers guidance on materials and design best practices.

- Is transparent about costs, MOQs, and lead times.

- Prioritizes quality and food safety standards.

By understanding these steps, you’re well-equipped to navigate the process of creating beautiful, durable, and unique plates that truly represent your vision.

FAQ: Your Custom Melamine Plate Questions Answered

Q1: What is the minimum order quantity (MOQ) for custom melamine plates?

MOQs typically range from 2,000 to 3,000 pieces per shape/size. Some suppliers may allow splitting this across a few designs, but each extra design will incur a decal setup fee.

Q2: How much does it cost to make custom melamine plates?

Costs vary based on quantity, plate size/complexity, number of print colors, material choice (A5 is standard), and if a new mold is needed. Expect per-unit costs, sampling fees, decal setup fees, and shipping. Get a detailed quote.

Q3: Can I print a full-color photograph on a melamine plate?

Yes, full-color photographic prints are possible. However, the quality of the original photo must be very high resolution. Discuss the specifics with your manufacturer, as results can vary based on the printing process and material.

Q4: Are custom printed melamine plates dishwasher safe and microwave safe?

Custom melamine plates (especially A5 grade) are generally dishwasher safe (top rack recommended, avoid harsh detergents or high-heat cycles). However, melamine is NOT microwave safe. Microwaving can cause the material to degrade, potentially leach chemicals, and become extremely hot.

Q5: How long does it take to get custom melamine plates made?

From design approval and PPS approval: manufacturing usually takes 30-60 days. Shipping then adds more time (a few days for air, weeks to months for sea). If a new mold is required, add several weeks to the initial phase.

Q6: What’s the difference between a “melamine plates manufacturer” and a “supplier”?

A manufacturer physically produces the plates in their factory. A supplier may be a trading company or agent that works closely with one or more manufacturers. Experienced suppliers can offer good service and access, but direct manufacturing often provides more control and potentially better pricing for larger orders.

Recommended:

- Melamine Plate Collecton from the Reliable Supplier

- FDA – Melamine in Tableware: Questions and Answers (Authoritative safety information)

- Incoterms® 2020 Explained by the ICC (Official source for shipping terms)